Why should I consider remote surveillance?

Operators encounter a wide spectrum of product features, benefits and pricing when selecting a plunger lift system. Controller prices alone range from $ 250 to over $ 5000. Less expensive systems offer limited settings and require local on-site control. Advanced systems offer a variety of control techniques, real-time optimization, plunger cycle diagnostics, e-mail / text alarms and even self-learning and self-adjusting algorithms. Are these new generation systems worth the cost?

Plunger lift systems are installed on gas wells for one purpose – to improve profits. When profits generated by production enhancements and decreased costs quickly exceed installation and operational costs – then the initial price tag becomes irrelevant. After the profit created by the system exceeds cost, all on-going benefits are enjoyed by the operator.

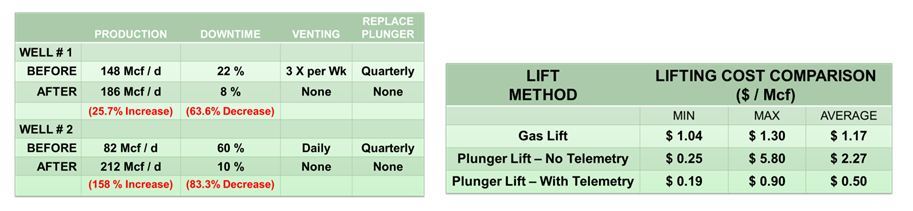

Viewing plunger lift purchasing decisions from a high level often reveals the true picture (See Fig 1). Standalone controllers (no telemetry) carry low prices, yet have on-going hidden fees. An on-site operator is necessary to optimize well performance. For well tenders driving over 100 miles a day to cover 60+ wells, little time exists to optimize production. For most, the goal decays to simply keeping the plunger cycling, a distant second to optimizing well performance. Simple controllers provide limited, unformatted data for troubleshooting and optimizing production. Root cause analysis diagnosing missed / fast /slow plunger arrivals is at best an educated guess. Unplanned downtime and equipment repair/maintenance is generally more frequent without real time surveillance. If a well shuts-in immediately after a well tender leaves the site, a day of lost production is possible before anyone knows the well is closed. Leak detection (motor valve, dump valve, etc) can take longer. Each of these issues increases the real cost of low priced controllers.

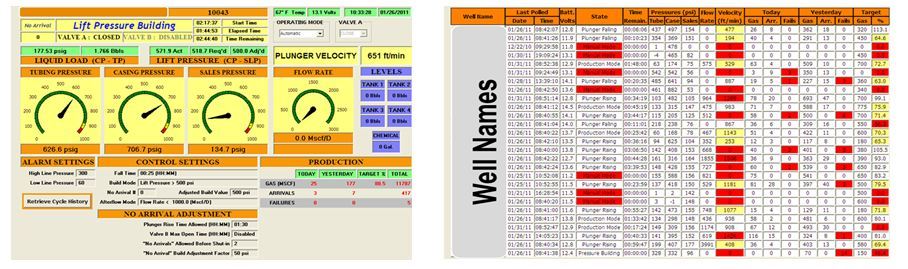

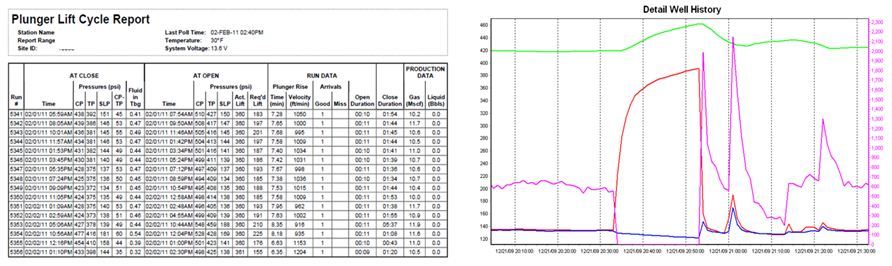

Advanced plunger lift systems enable real-time well surveillance and optimization. It’s like having an operator on site 24 hours a day – something none could afford, yet all readily admit the benefits of doing so. Immediate knowledge and response to a well’s needs improve production and safety while reducing costs. Real time e-mail alerts provide operators with immediate knowledge of plunger cycles and well site conditions. Informative, detailed data (See Fig 2, 3) presented in an intuitive actionable format enables good decisions. Controllers with advanced telemetry provide the means for a skilled plunger lift technician to optimize many wells without non-productive drive time.

When operators know now and act now, wells will produce more.

Fig 1. Plunger lift before and after remote surveillance and optimization