What is plunger lift?

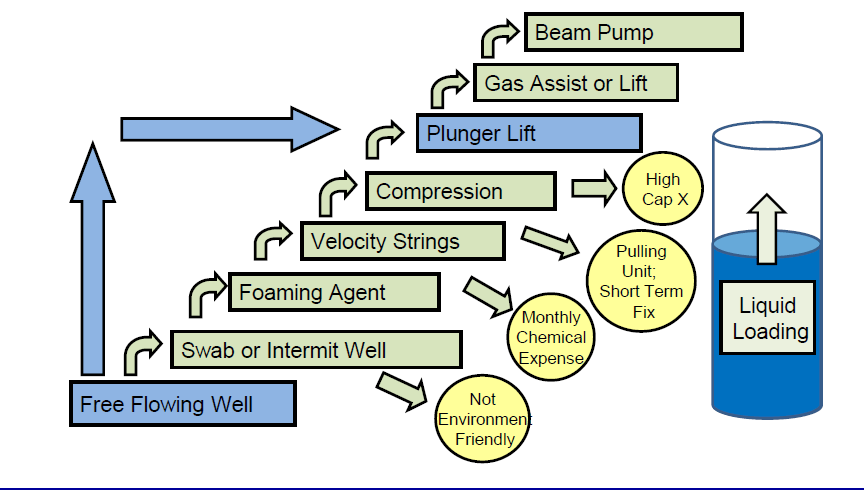

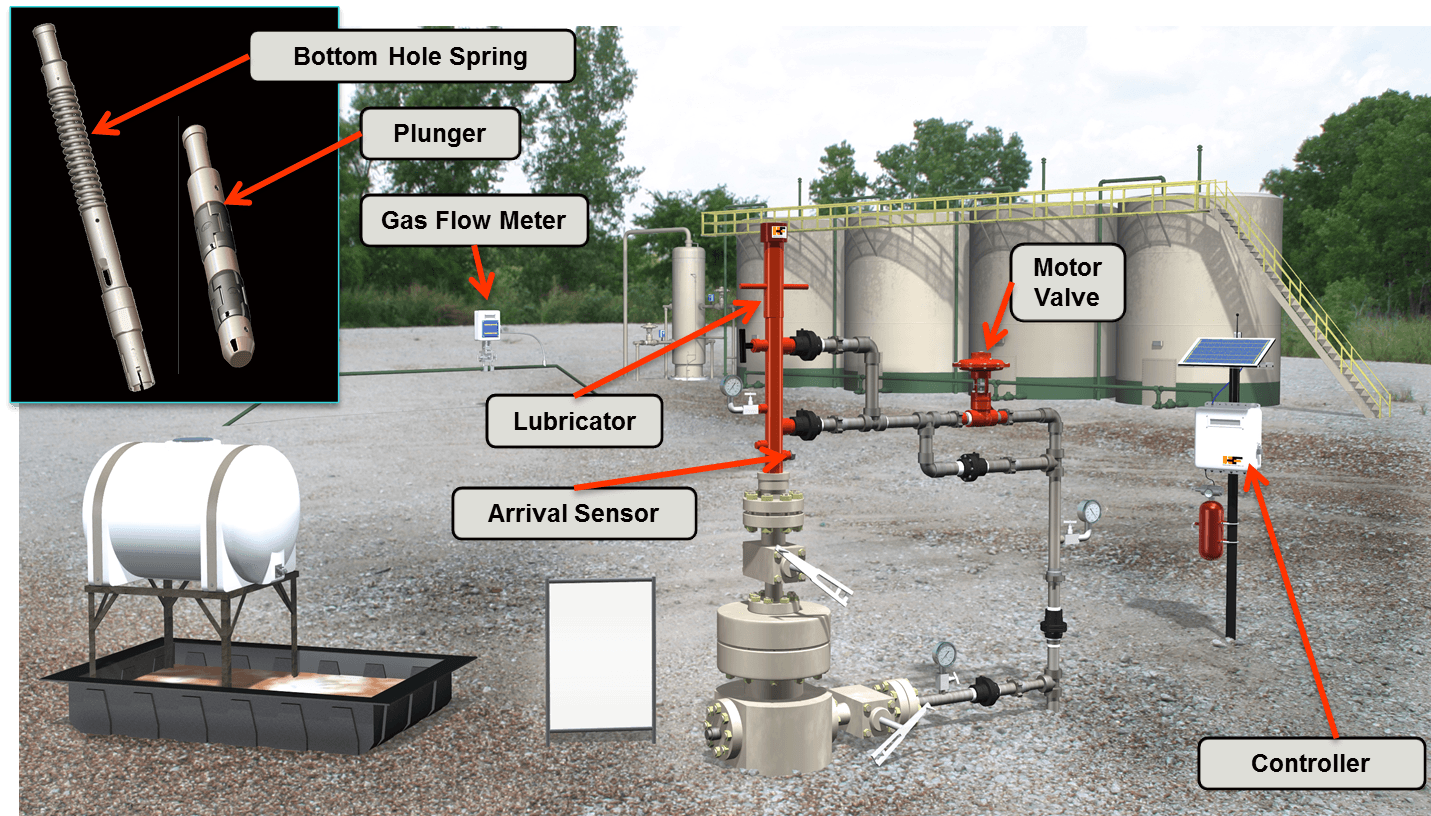

Plunger lift is an economical, environmentally friendly artificial lift method (See Fig 1) to remove liquid from wells using the wells internal energy. A typical system consists of a plunger, bottom-hole spring assembly, lubricator, arrival sensor, controller, motor valve and gas flow meter (See Fig 2). Solar charged batteries power the electronics, ensuring no additional energy sources are required at the well site. Gas and liquids are produced through the tubing on plunger lifted wells, with the casing valve closed. The free-floating plunger cycles in the tubing, rising when the well is open and falling when it is closed. The plunger acts as an interface between the gas energy below and the liquid column above the plunger.

A plunger lift cycle consists of four basic steps:

- Plunger Fall Mode – well closed, plunger is falling toward the bottom hole spring location

- Pressure Build Mode – plunger on bottom, well is closed until the open set point occurs

- Plunger Rise Mode – open set point occurs, well is opened, plunger begins it’s ascent

- Production Mode – plunger surfaces, arrival sensor notifies the controller, gas beneath the plunger is produced

Once the production mode expires, the controller re-initiates the plunger fall mode.

Plunger lift has been around since the 1920’s based on patent records, and maybe before. In the early days, controllers were large mechanical timers and plungers were often referred to as “rabbits” going down the hole (well bore).

With the advancement of electronic controllers, the application and efficiency of plunger lift to remove liquids from qualified wells has greatly increased.